A late-night factory floor once meant long lines of tired workers stacking boxes by hand. Today, that picture feels outdated. Automation quietly changed everything. Packaging operations now demand speed, consistency, and safety at the same time. This article explores how robotic technologies redefine packaging lines, focusing on intelligent cartoning and advanced case packing while explaining why these systems matter for competitive manufacturing environments. Progress waits for nobody.

Packaging Automation Is No Longer Optional

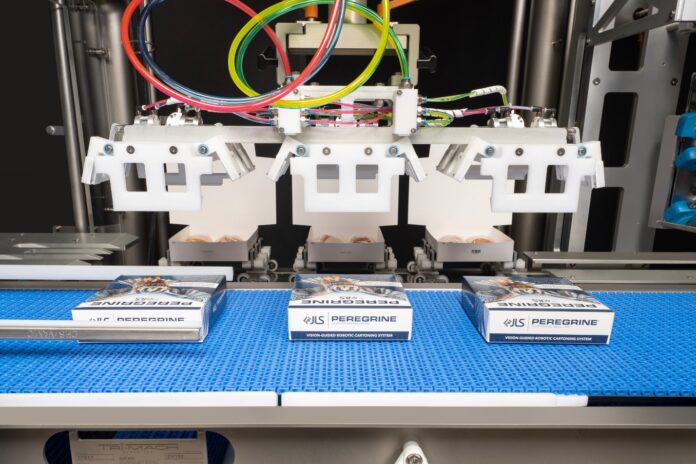

Manufacturing environments face constant pressure to move faster while maintaining accuracy and hygiene. Manual packaging struggles to keep pace. This is where a robotic cartoning system transforms operations by automating carton forming, loading, and sealing with impressive precision. It reduces repetitive labor stress, improves output consistency, and supports flexible production demands without slowing down during product changeovers. Efficiency becomes routine, not exceptional.

Design Precision Meets Industrial Reality

Modern automation equipment is engineered for real production challenges, not theory. A robotic cartoning system handles varied package sizes, materials, and speeds without frequent adjustments. Sensors, vision guidance, and controlled motion ensure accurate placement every cycle. Downtime drops noticeably. Maintenance becomes predictable. This balance between precision engineering and rugged performance keeps production schedules realistic and dependable.

Case Packing Evolves With Robotics

Secondary packaging often becomes the bottleneck. Traditional methods rely heavily on manual handling, increasing error rates. Robotic case packers solve this issue by loading products into cases at high speed with controlled force and accuracy. They manage delicate items just as well as heavy products. Consistency improves. Line efficiency stabilizes. Production planning feels easier again.

Flexibility Becomes A Competitive Advantage

Packaging lines rarely stay the same for long. Seasonal demand, new product launches, and packaging redesigns are constant realities. Robotic case packers adapt quickly to these shifts through programmable configurations and modular tooling. This flexibility reduces costly downtime during transitions. Changeovers stop being a headache. Operations stay responsive instead of reactive.

Data-Driven Packaging Performance Gains

Automation today is not just mechanical. Integrated data tracking allows performance monitoring in real time. A robotic cartoning system provides insights into cycle times, fault trends, and throughput consistency. Decisions become informed rather than guessed. Small adjustments deliver measurable gains. One small delay fixed can unlock hours of saved production time. Simple wins matter.

Workforce Safety And Quality Control

Reducing manual handling improves workplace safety significantly. Repetitive strain injuries decline as robotic case packers take over heavy lifting and awkward movements. Quality also benefits from reduced human error. Packages look uniform. Seals stay intact. Brand presentation improves quietly. Fewer mistakes. Less waste. That alone justifies investment for many operations.

Conclusion

Automation in packaging is no longer a future concept; it defines current industry standards. Intelligent systems deliver speed, reliability, and adaptability while supporting safer work environments. Operations that embrace these technologies position themselves for sustainable growth, smoother workflows, and long-term efficiency. The shift is already happening. Standing still is the real risk.

Great insights in this post—thanks for sharing practical tips and thoughtful perspectives that help readers consider reliable options and make informed decisions when choosing new gear for busy offices Epson Printer distributor dubai.

As a neighbourly reader, I appreciate thoughtful updates on home projects that boost curb appeal and value, while keeping the vibe friendly and practical for families across the area Multi-Family Exterior Renovations Services in Pickerington.

I really appreciate how this post celebrates inner strength and positivity. The message feels uplifting and relatable, encouraging readers to prioritise kindness towards themselves while staying curious about the world. It’s a gentle reminder that small, consistent habits can spark real change self love t shirt.

I loved reading this post and it really captures the thrill of hitting the road with fellow riders. The scenery sounds stunning, and the warm, practical tips make me feel ready to plan a peaceful ride through beautiful routes and charming towns Guided Motorcycle Tours Across in Europe.

What a thrilling read! I love hearing about routes that balance scenic landscapes with smooth roads and charming pit stops. Your writing captures the excitement and little moments that make a journey memorable. Definitely inspiring for anyone planning their next two-wheeled adventure Alps Motorcycle Tour.

What a fascinating read! It’s refreshing to see practical tips balanced with personal stories, making planning feel approachable for riders at every level. Thanks for sharing thoughtful perspectives and ideas Motorcycle Touring Company.

I recently explored shopping options for reliable gear and found excellent guidance on how to compare prices and warranties. It’s reassuring when vendors clearly explain features, service policies, and delivery timelines, helping buyers feel confident about their purchase decisions in any market Epson Printer Sellers Russia.

Great post! I appreciate the balanced view on cost, reliability, and safety in logistics, and I’d love to hear more about how local partnerships can streamline cross-border shipping for manufacturers and suppliers Maquiladora Transportation San Diego.

Love reading this post and the way it captures the open road’s freedom and small-town charm. It’s the kind of journey that sparks curiosity, conversation, and new road trips with friends Motorcycle Touring Company.

Love reading this post and the way it captures the open road’s freedom and small-town charm. It’s the kind of journey that sparks curiosity, conversation, and new road trips with friends Motorcycle Touring Company.

Your thoughtful post really resonated with me; it’s nice to see messages that focus on kindness and connection, reminding everyone to pause, breathe, and approach life with genuine curiosity and care you matter apparel.